young's modulus glass

E-Glass fibre is the most commonly used glass fibre for fibreglass. 72 GPa 10440.

This article outlines its production and some of its applications.

. Youngs modulus GPa polystyrene C 8 H 8 n. Reasons for its use properties advantages and disadvantages are covered as are production methods. E-Glass fibre is the most commonly used glass fibre for fibreglass.

Youngs modulus GPa glass-70. When volume fraction of the fibers is 88. Here as an alternative route we combine machine learning with high-throughput molecular dynamics simulations to predict the Youngs modulus of silicate glasses.

That is tensile or compressive stress in one direction and no stress in the other directions. The Youngs modulus directly applies to cases of uniaxial stress. Float glass provides the material for all other forms of processed glass such as laminated glass and toughened glass.

There is no formula for Youngs Modulus. To predict the Youngs moduli of the oxide glass systems empirical compositional parameters Gi and Vi based on the Makishima-Mackenzie theory were obtained where Gi is the dissociation energy and Vi the packing density parameter of a single-component oxide. The values here are approximate and only meant for relative comparison.

E-glassalso known as electrical glassis the standard glass composition used for most glass fibers. Youngs modulus of the starting iron phosphate glass F40 40Fe 2 O 3 60P 2 O 5 mol is also given in Table 2. Polyvinylchloride PVC CH 2 CHCl n.

Youngs modulus can vary somewhat due to differences in sample composition and test method. Physical Properties of Glass. Youngs modulus is the slope of the linear part of a stress-strain diagram so it is basically a test result.

It can be thought of as a material. Youngs modulus or storage modulus is a mechanical property that measures the stiffness of a solid material. Teflon polytetrafluoroethylene PTFE C 2 F 4 n.

The rate of deformation has the greatest impact on the data collected especially in polymers. Medium density fiberboard MDF-4. It is the ratio of tensile stress to tensile strain.

Youngs modulus is also used in order to predict the deflect. Youngs modulus is the slope of the linear part of a stress-strain diagram so it is basically a test result. It is a measure of volumetric elasticity calculated as volumetric stress divided by volumetric strain.

It is expressed as a force per unit areaFor glass in accordance with. We demonstrate that this combined approach offers good and reliable predictions over the entire compositional domain. It defines the relationship between Stress Stress is defined as a level of force applied on a sample with a well-defined cross section.

Float glass provides the material for all other forms of processed glass such as laminated glass and toughened glass. Material GPa lbfin² psi Rubber small strain 00101. This glass has the best chemical durability smallest dissolu- tion rate in.

Fibers have higher strengths Theoretical Strength of Glass Units Primer System Property Units Fundamental Conversion Standard International Pressure Stress Pascal Pa Nm2 kgm-sec2. We use cookies to. And transverse Youngs modulus of the glass fiber- reinforced composites at different volume fraction of the fibers has been shown in Fig.

For instance it predicts how much a material sample extends under tension or shortens under compression. This article outlines its production and some of its applications. 3400 MPa 490 ksi Modulus of elasticity.

Polypropylene CH 2 CHCH 3n. Reasons for its use properties advantages and disadvantages are covered as are production methods. Discovering new glasses with improved mechanical properties is key to address present and future challenges in energy communication and infrastructure Among all the mechanical properties that are of interest to glasses the Youngs modulus E plays a critical role in the performance of glass fibers More generally the Youngs.

Youngs modulus E This modulus expresses the tensile force that would theoretically have to be applied to a glass sample to stretch it by an amount equal to its original length. It exhibits the following mechanical properties. Approximate Youngs modulus for various materials.

254 gcm 3 1586 lbft 3 Tensile strength. Youngs modulus describes tensile elasticity along a line when opposing forces are applied. It is made from the oxides of silicon aluminum calcium magnesium and boron.

ÆManufactured glass has nominal strength of 70 MPa 10 KPsi ÆDesign stresses often 7 MPa or less for high reliability structures ÆLow surface area structures eg. By comparing the performances of select machine learning algorithms. The bulk modulus K is like Youngs modulus except in three dimensions.

Youngs modulus enables the calculation of the change in the dimension of a bar made of an isotropic elastic material under tensile or compressive loads.

Elastic Modulus Properties For The Reinforced E Glass Epoxy Composite Plate Download Table

Problem A Measure Of Degree Of Orthotropy Of A Chegg Com

An Approach For Measurement Of Young S Modulus Of Glass In The Form Of A Slab Semantic Scholar

Longitudinal Young S Modulus For A 20 Glass Fiber Filled Polypropylene Download Scientific Diagram

Glass Transition Temperature And Young S Modulus As A Function Of Mmt Download Scientific Diagram

Young S Modulus Of Silver Glass Vs Temp Download Scientific Diagram

Elastic Modulus Young S Modulus Of Glasses

Pdf Influence Of The Testing Gage Length On The Strength Young S Modulus And Weibull Modulus Of Carbon Fibres And Glass Fibres Semantic Scholar

Young S Modulus E And Tensile Strength Of Glass Bers Download Table

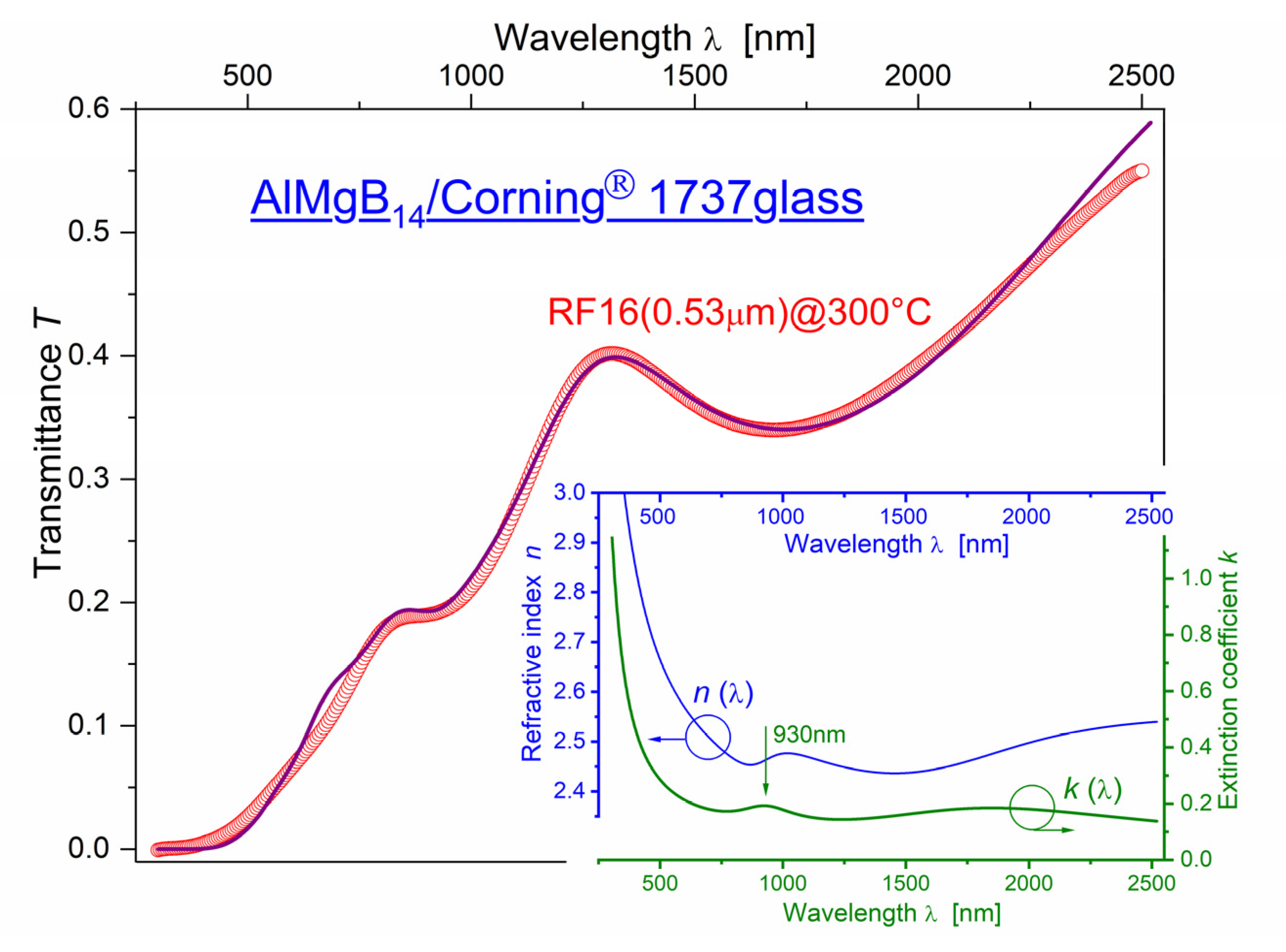

Crystals Free Full Text Hardness Young S Modulus And Elastic Recovery In Magnetron Sputtered Amorphous Almgb14 Films Html

Young S Modulus E And Tensile Strength Of Glass Bers Download Table

Young S Modulus Wiki Thereaderwiki

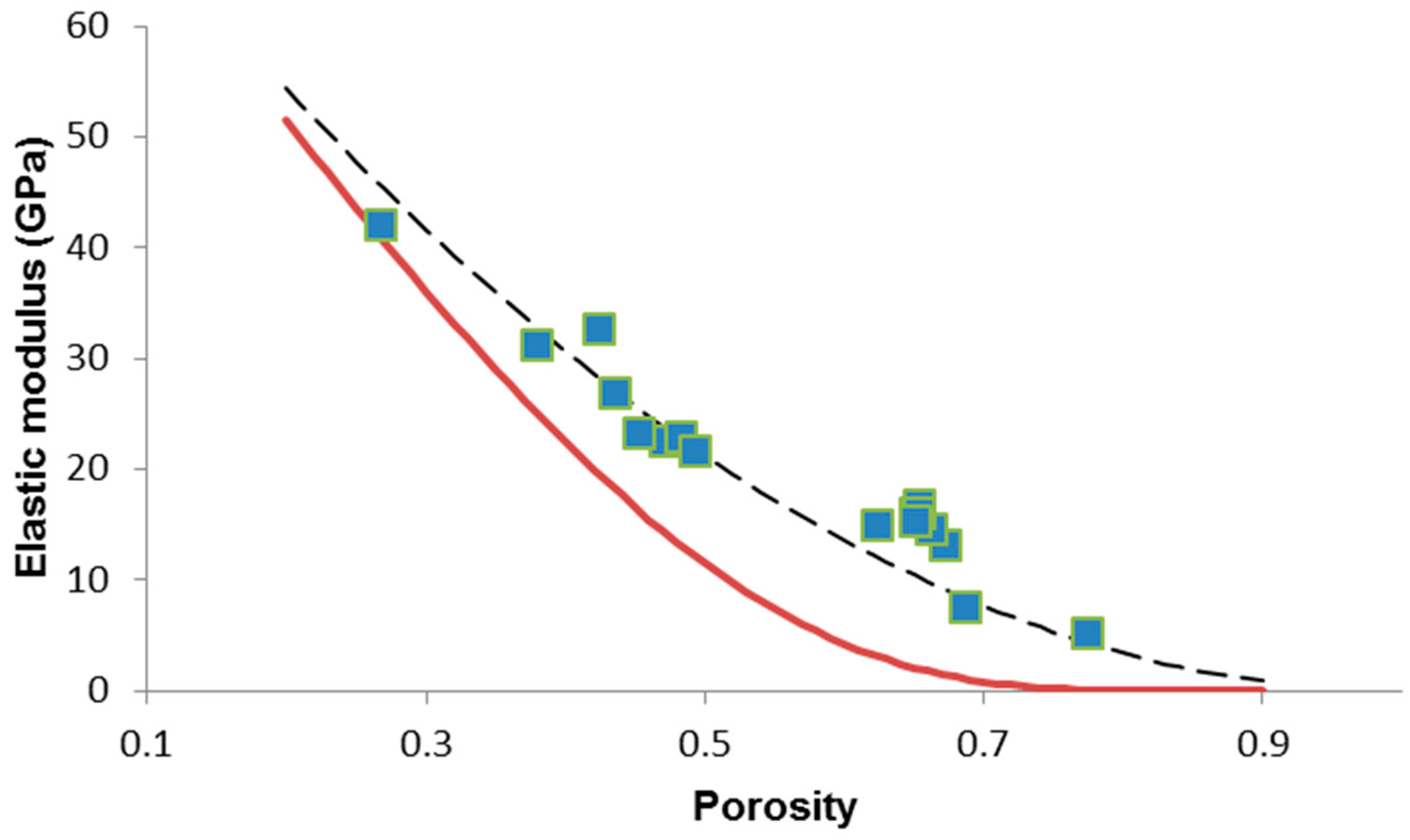

Materials Free Full Text Elastic Mechanical Properties Of 45s5 Based Bioactive Glass Ceramic Scaffolds Html

Young S Modulus Of The Glass Fiber Reinforced Composites In Download Scientific Diagram

Shear Modulus Calculation Of Glasses

0 Response to "young's modulus glass"

Post a Comment